Background: Difference between revisions

No edit summary |

|||

| Line 10: | Line 10: | ||

==Historical Background== | ==Historical Background== | ||

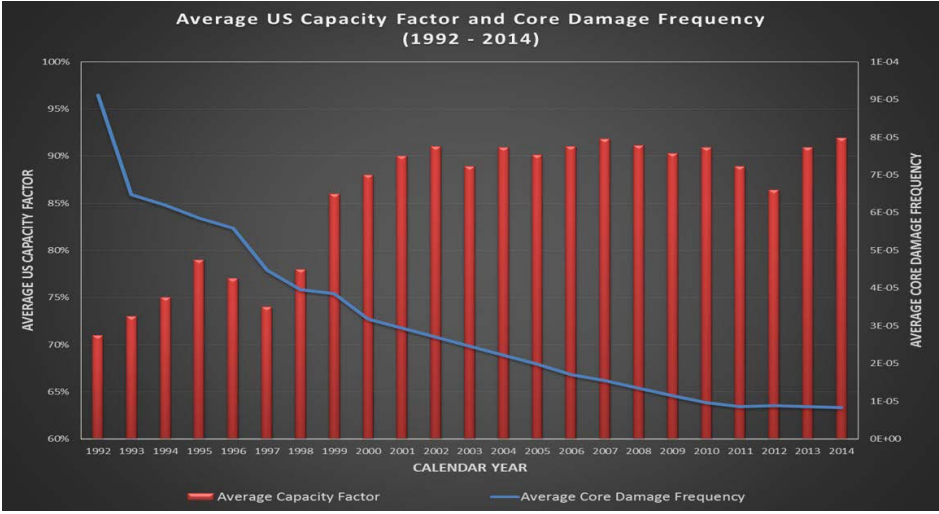

In the current fleet of US LWRs, a measurable improvement of safety can be seen in the figure below which displays increasing plant capacity factors as a measure of operational performance with a simultaneous decrease in average estimated plant core damage frequency. | In the current fleet of US LWRs, a measurable improvement of safety can be seen in the figure below which displays increasing plant capacity factors as a measure of operational performance with a simultaneous decrease in average estimated plant core damage frequency. PRA applications have made a significant contribution to both plant safety and operational flexibility and performance. | ||

<br><br> | <br><br> | ||

[[File:cdf.png]] | [[File:cdf.png]] | ||

<br><br> | <br><br> | ||

A PRA model is required as part of risk-informed licensing basis for new light water reactors (LWRs) under [https://www.nrc.gov/reading-rm/doc-collections/cfr/part052/index.html Part 52 of 10 CFR] [[References|[2]]] (NRC) and for advanced reactor deployments, [https://www.nrc.gov/reading-rm/doc-collections/cfr/part050/part050-appa.html 10CFR50] [[References|[11]]] section 34(f)(1)(i) states that the license applicant “Perform a plant/site specific probabilistic risk assessment, the aim of which is to seek such improvements in the reliability of core and containment heat removal systems that are significant and practical and do not impact excessively on the plant.” To reflect the large gap in the designs of current LWRs and Advanced Reactors (ARs), a standard that specifies requirements for developing a PRA for non-LWR advanced reactors has been developed and because licensing and operation of these advanced reactors represent a First of a Kind (FOAK) application, the US nuclear industry developed guidance [https://www.nrc.gov/docs/ML1924/ML19241A472.pdf (NEI 18-04)] [[References|[8]]] for a modern, technology-inclusive, risk-informed, and performance-based (TI-RI-PB) process. Proposed AR designs include power ranges from tens of megawatts to thousands of megawatts. The primary end use for ARs focused on in this research is electric power production. The core types of the ARs include solid fuels, balls or blades, liquid fuels, solid fuels with liquid or gaseous coolants, and multi module cores. The wide range of core types also implies a wide range of fuel types from existing fuels to nonconventional advanced fuels such as molten fuel. New AR designs include state-of-the-art passive safety designs and digital I&C, which is not included in most traditional LWRs. Different avenues of radiation release are considered as a result of variation in reactor design. Potential events include CD in a reactor vessel or distributed fluid system associated with molten core designs, and fuel damage in spent fuel pools. PRA for existing reactors includes up to level 3 for quantification of initiating events and all hazards, while for advanced reactors the quantification level capability may vary from plant to plant. | A PRA model is required as part of risk-informed licensing basis for new light water reactors (LWRs) under [https://www.nrc.gov/reading-rm/doc-collections/cfr/part052/index.html Part 52 of 10 CFR] [[References|[2]]] (NRC) and for advanced reactor deployments, [https://www.nrc.gov/reading-rm/doc-collections/cfr/part050/part050-appa.html 10CFR50] [[References|[11]]] section 34(f)(1)(i) states that the license applicant “Perform a plant/site specific probabilistic risk assessment, the aim of which is to seek such improvements in the reliability of core and containment heat removal systems that are significant and practical and do not impact excessively on the plant.” To reflect the large gap in the designs of current LWRs and Advanced Reactors (ARs), a standard that specifies requirements for developing a PRA for non-LWR advanced reactors has been developed and because licensing and operation of these advanced reactors represent a First of a Kind (FOAK) application, the US nuclear industry developed guidance [https://www.nrc.gov/docs/ML1924/ML19241A472.pdf (NEI 18-04)] [[References|[8]]] for a modern, technology-inclusive, risk-informed, and performance-based (TI-RI-PB) process. Proposed AR designs include power ranges from tens of megawatts to thousands of megawatts. The primary end use for ARs focused on in this research is electric power production. The core types of the ARs include solid fuels, balls or blades, liquid fuels, solid fuels with liquid or gaseous coolants, and multi module cores. The wide range of core types also implies a wide range of fuel types from existing fuels to nonconventional advanced fuels such as molten fuel. New AR designs include state-of-the-art passive safety designs and digital I&C, which is not included in most traditional LWRs. Different avenues of radiation release are considered as a result of variation in reactor design. Potential events include CD in a reactor vessel or distributed fluid system associated with molten core designs, and fuel damage in spent fuel pools. PRA for existing reactors includes up to level 3 for quantification of initiating events and all hazards, while for advanced reactors the quantification level capability may vary from plant to plant. | ||

Revision as of 20:30, 5 July 2024

Objective / Purpose

The background of how risk assessment is applied to advanced reactors largely involves looking at risk assessment methods that were developed for the current fleet of reactors and how this can be applied to advanced reactors.

Why Risk

Risk assessment methods and applications have a rich history since plants in the U.S. developed Probabilistic Risk Assessments (PRAs) in the early 1990s. PRA and its applications are now a daily part of effective plant operation not only in the U.S., but globally. As new plant designs are under development, PRA is an integral part of the design and licensing process. Historical insights gleaned from the use of risk methods in existing fleets can inform the application of risk for advanced designs.

Scope

Probabilistic Risk Assessment (PRA) is a required part of the risk informed license following the WASH-1400 Study [1] due to its proven benefits as applied to LWRs over the past 40 years. PRA technology and its applications have given rise to the development, not only of risk-informed applications, but also risk-informed regulation over a period of about 30 years. This has been a rapid transition from a narrow and highly technical field to daily use of PRA in plant operations and regulation at present. The scope of this effort is to investigate the historical aspects of risk technology, regulation and guidance for its applicability to advanced designs. Since advanced reactor / non-LWR designs can vary quite drastically from the designs of current LWRs, creating guidance and specific requirements for a PRA equivalent of advanced reactors can pose challenges.

Historical Background

In the current fleet of US LWRs, a measurable improvement of safety can be seen in the figure below which displays increasing plant capacity factors as a measure of operational performance with a simultaneous decrease in average estimated plant core damage frequency. PRA applications have made a significant contribution to both plant safety and operational flexibility and performance.

A PRA model is required as part of risk-informed licensing basis for new light water reactors (LWRs) under Part 52 of 10 CFR [2] (NRC) and for advanced reactor deployments, 10CFR50 [11] section 34(f)(1)(i) states that the license applicant “Perform a plant/site specific probabilistic risk assessment, the aim of which is to seek such improvements in the reliability of core and containment heat removal systems that are significant and practical and do not impact excessively on the plant.” To reflect the large gap in the designs of current LWRs and Advanced Reactors (ARs), a standard that specifies requirements for developing a PRA for non-LWR advanced reactors has been developed and because licensing and operation of these advanced reactors represent a First of a Kind (FOAK) application, the US nuclear industry developed guidance (NEI 18-04) [8] for a modern, technology-inclusive, risk-informed, and performance-based (TI-RI-PB) process. Proposed AR designs include power ranges from tens of megawatts to thousands of megawatts. The primary end use for ARs focused on in this research is electric power production. The core types of the ARs include solid fuels, balls or blades, liquid fuels, solid fuels with liquid or gaseous coolants, and multi module cores. The wide range of core types also implies a wide range of fuel types from existing fuels to nonconventional advanced fuels such as molten fuel. New AR designs include state-of-the-art passive safety designs and digital I&C, which is not included in most traditional LWRs. Different avenues of radiation release are considered as a result of variation in reactor design. Potential events include CD in a reactor vessel or distributed fluid system associated with molten core designs, and fuel damage in spent fuel pools. PRA for existing reactors includes up to level 3 for quantification of initiating events and all hazards, while for advanced reactors the quantification level capability may vary from plant to plant.